Steel Detailing is a type of engineering that involves producing detailed plans and drawings for steel fabricators and erectors. The work of a steel detailer is very important in the construction industry because it helps engineers create exact designs for steel members used in buildings. Here are some of the most common tasks performed by a steel detailer. This article will help you choose the right career path. Steel Detailing is a great career for engineers, as it offers a great deal of job satisfaction.

Steel detailing is a specialty of structural drafting. It includes the production of shop drawings for structural steel fabrication. These drawings provide erectors with the specifications necessary to properly erect a steel member. Detailing is often done in conjunction with architects and engineers, but can also be done by steel fabricators themselves. Once a design is in place, a detailer can begin the fabrication process. After all, this is one of the first steps in the construction process.

A structural steel detailer can advance to the position of project manager. This role requires them to oversee the work of a team of detailers and ensure that each project is completed according to schedule and budget. Get Steel Detailing Services from Dowco.They may also be responsible for marketing the service of the steel detailer and negotiating contracts. Other roles that structural steel detailers may fulfill are estimator, sales manager, and operations manager. Listed below are some of the roles that are typically performed by a structural steel detailer.

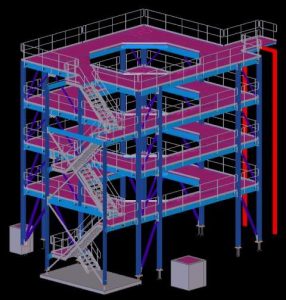

Steel Detailing drawings show the overall layout and size of the steel components. They also display how the steel components interact with one another. A steel detail drawing includes information about the connection between steel components, as well as its fireproofing requirements. The drawings are typically made using manual drafting methods, such as pencils and paper. Later, the practice was digitized with the use of CAD software. If you’re looking to improve your skills in steel detailing, the best course of action is to get a BIM-enabled 3D steel detailing solution.

Professional certifications for steel detailers help you gain expert knowledge of different fields. By becoming certified, you may enhance your knowledge of basic designing and drafting principles. By earning certifications, you can also improve your skills and proficiency with structural design software. You should also get BIM services. And as a steel detailer, you may even want to pursue education. And to further increase your chances of securing a steel detailing job, you can also pursue further studies in the field.

A steel detailer is a professional who creates detailed shop drawings for steel fabricators. They create blueprints and plans that show steel sizes and positions for the fabrication and installation of the structure. In addition to building plans, steel detailing involves detailed structural drawings and correspondence between key individuals. This collaboration is necessary to keep the debacles under control. There are many important aspects of steel detailing. You should be familiar with all of them before you choose the right type of steel detailing for your project.

Erection drawings give a detailed plan for the entire construction site. This type of drawing contains all the required materials and dimensional plans for each steel member. It is important to use erection drawings as a blueprint before you start construction. The drawings should be approved by your architect or structural engineer. The final steps of steel detail will be a success if you have it correctly drawn. For this type of project, you need a professional with experience and expertise.

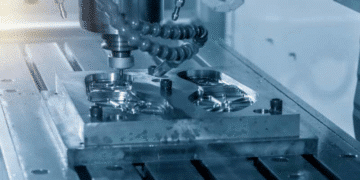

CAD software is the preferred software of structural steel detailers. It is a 3D modeling software that enables steel detailers to create detailed shop drawings. Steel detailing software provides all of the necessary tools to create detailed drawings. You can also download your drawings directly into CNC files, which allow your steel fabricator to start drilling and cutting parts. These programs are useful for steel fabricators and erectors to collaborate with each other efficiently and accurately.

The process of structural steel detailing is an important part of structural engineering. It requires near-perfect accuracy, and even the smallest error could lead to massive losses in time and money. Errorless steel detailing is an important step towards quality building structures and products. It also provides a common communication link between various key professionals who have individual responsibilities for quality steel structures. You may have a team of professionals involved in structural steel detailing, but it can also bring in the next level of professionalism.