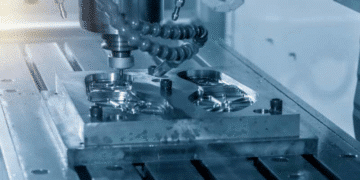

Sanitation in the plant is an essential aspect of the process of making food. The requirements for hygiene for food production are demanding that food manufacturers must undergo strict hygiene protocols to ensure compliance with the government’s guidelines on sanitation of food plants. The sanitation process begins by knowing the kind of infection that exists within the facility. Food manufacturing facilities that are Ak assainissement sanitized might follow the same steps however, each food producer might have their own cleaning protocols, in accordance with their particular requirements.

- The first thing to be completed is to get rid of bulk debris. These are huge chunks of waste and leftover materials after processing. This can be eliminated by hand. Food production and brewery sanitation services begin with the elimination of all large remnants. The disposal of large pieces of waste is the first step of any general cleaning or sanitation job.

- Rinsing should be the 2nd step following the time that all debris has been removed from the area. The equipment and the facility within it must be cleaned with fresh water. A lot of manufacturers employ distilled or de-ionized water. This is thought to aid in cleaning. The plain water could cause scales to form on the equipment’s surface. However the initial water to rinse must be warm.

- Cleaning agents are chemicals employed to eliminate hard-to-clean dirt and also disinfect the surface. Cleaning staff should follow the directions regarding the proper use of the particular cleaner. Cleaning products contain harmful chemicals that could cause burns if misused. Cleaning agents that are strong can release fumes which can cause suffocation or burning of the lining of the airway for anyone who gets in contact with them. Cleaning solutions come with an Material Safety Data Sheet that explains how it should be used and what precautions need to be taken. For example, the use of goggles, gloves or face masks, as well as safety boots are sometimes required.

- The area must be washed another time to eliminate the cleansing chemicals along with the dirt. It is vital to rinse thoroughly since chemical residues can be harmful to food items. In general warm water is utilized to rinse. It is usually the last stage of rinsing. However, many manufacturers opt to repeat the process to ensure the proper hygiene.

- Sanitizers are generally the final step. Sanitizers eliminate any the remaining bacteria and harmful microorganisms which may have survived previous cleaning procedures. Sanitizers can only be added when the area is completely cleaned. If not the benefits of the sanitizer could be minimal. It is possible that they will require washing off after a time, however certain sanitizing agents are sufficient to last in place without needing to rinse off.

Food cleaning in the plant is a tough job that requires the efforts from a number of employees. Instruments that are specially designed can also be employed, and the people who are cleaning the area need to be aware of how to use the instruments. In addition, the cleaning process must be carried out correctly otherwise, it could cause the formation of chemical and dirt residues that could become the source of infection.